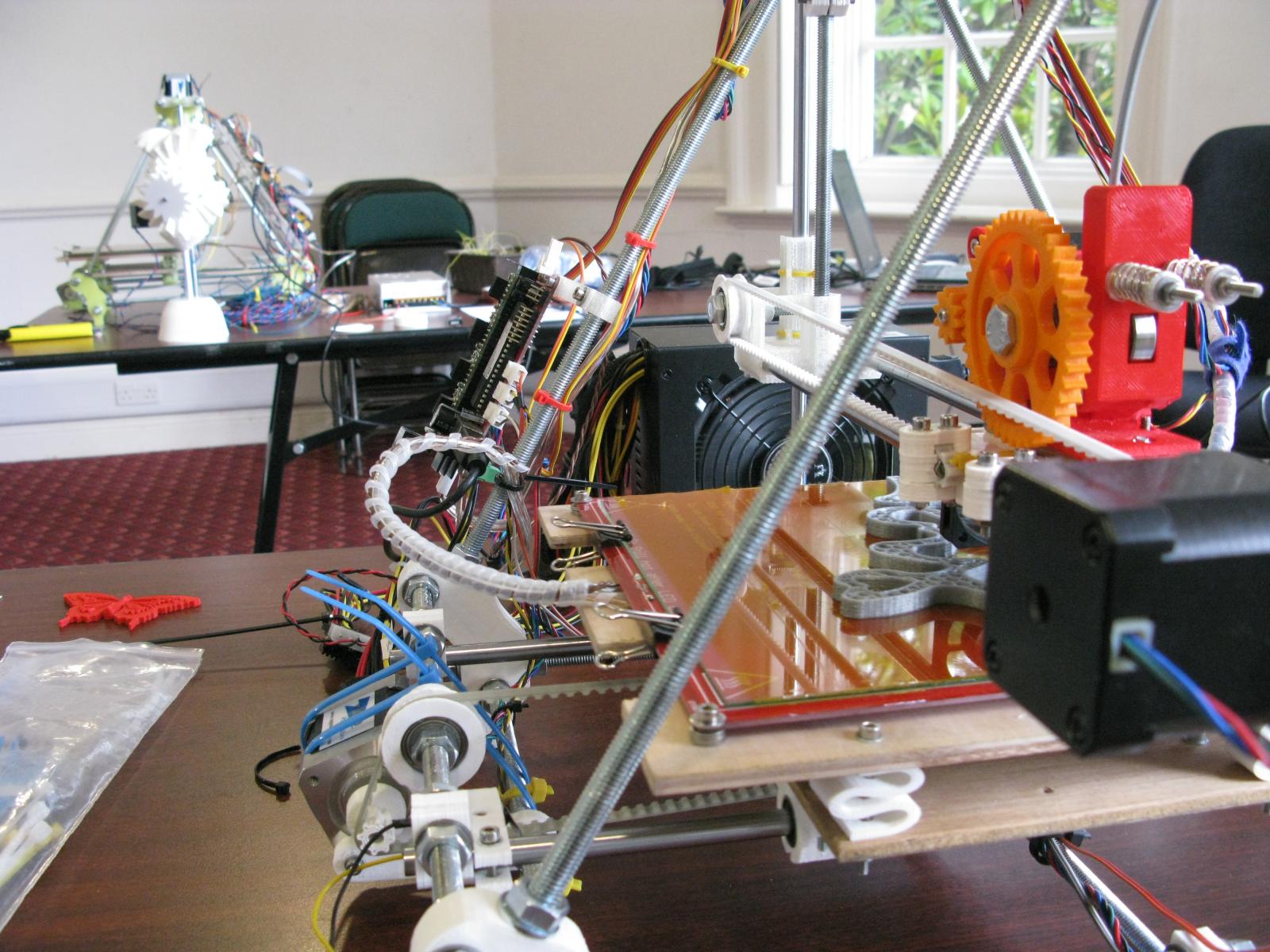

I am a meta-cognitive, 230 axis, 3D printer.

Josh Bitelli is a recent Design graduate from the University of Brighton who we met at Brighton Mini Maker Faire last year. His work ‘3D Drawings‘ returns the craftsmanship to the additive manufacturing process by creating the objects by hand, using trigger-based extrusion tools such as glue guns or mig welders. It was exhibited as part of the New Designers 2012 exhibition in London, which sadly we didn’t manage to attend.

I love the texture of the pieces. Josh told us that for the stainless steel mig welded items, the nature of the arc welding process creates a unreproducible surface finish every time for truly unique objects.

This also raises exciting possibilities for 3D printers – these trigger-based extrusion tools could open doors to new affordable materials, such as stainless steel. Anyone up for building a mig-welder 3D printer?