If you have wonky circles or infill not meeting the edges in your prints, then you likely have backlash. There are several potential causes of backlash in your 3D printer, which makes it a particularly tricky problem to iron out. I’ve been trying to eliminate the backlash in Mendel, and have had some success.

According to Wikipedia, backlash is the amount of lost motion due to clearance or slackness when movement is reversed and contact is re-established

. The reversal of movement is key in the definition, hence why backlash problems show up in circles (each axis reverses direction twice drawing a circle) and when infill meets perimeter.

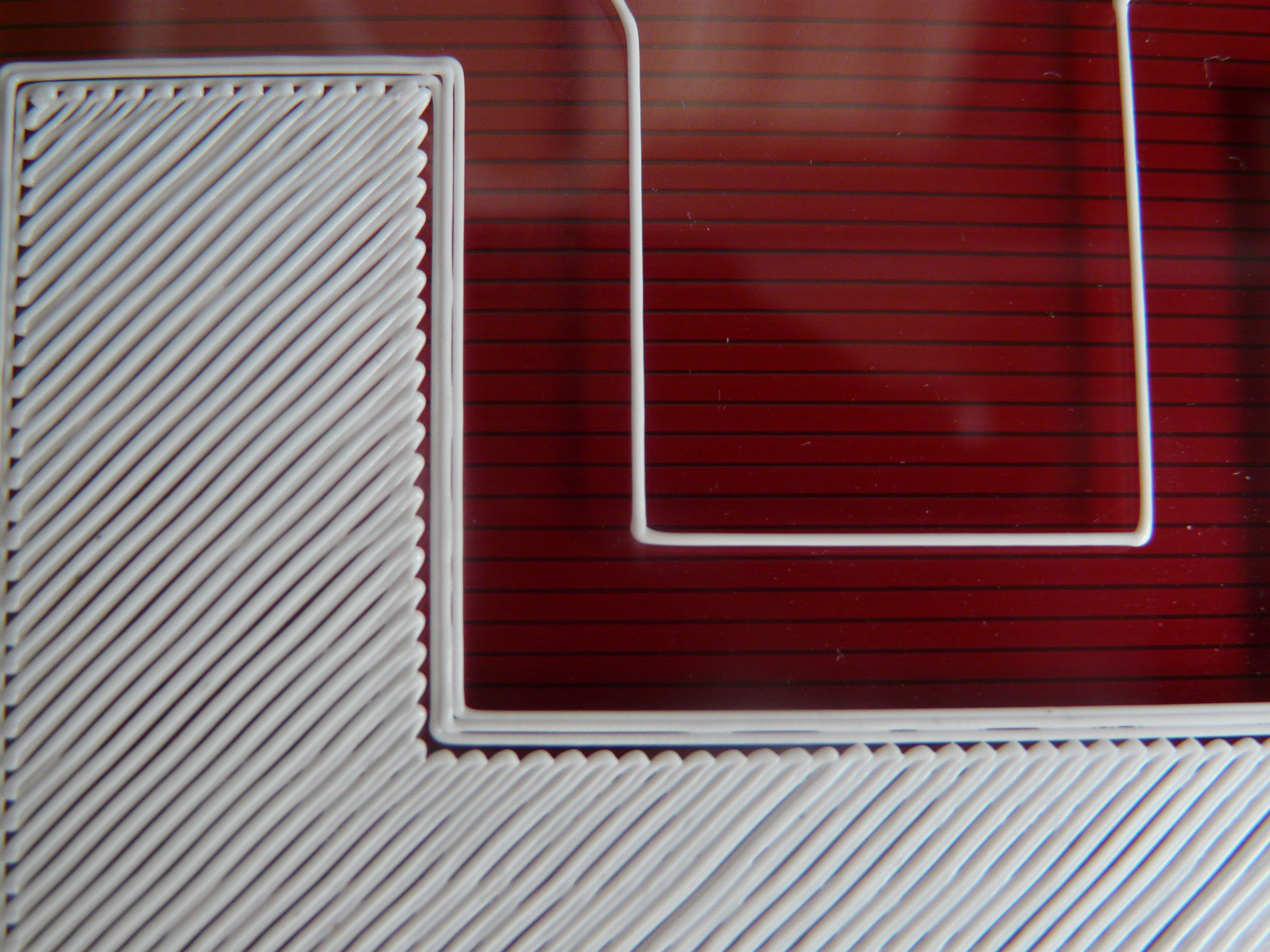

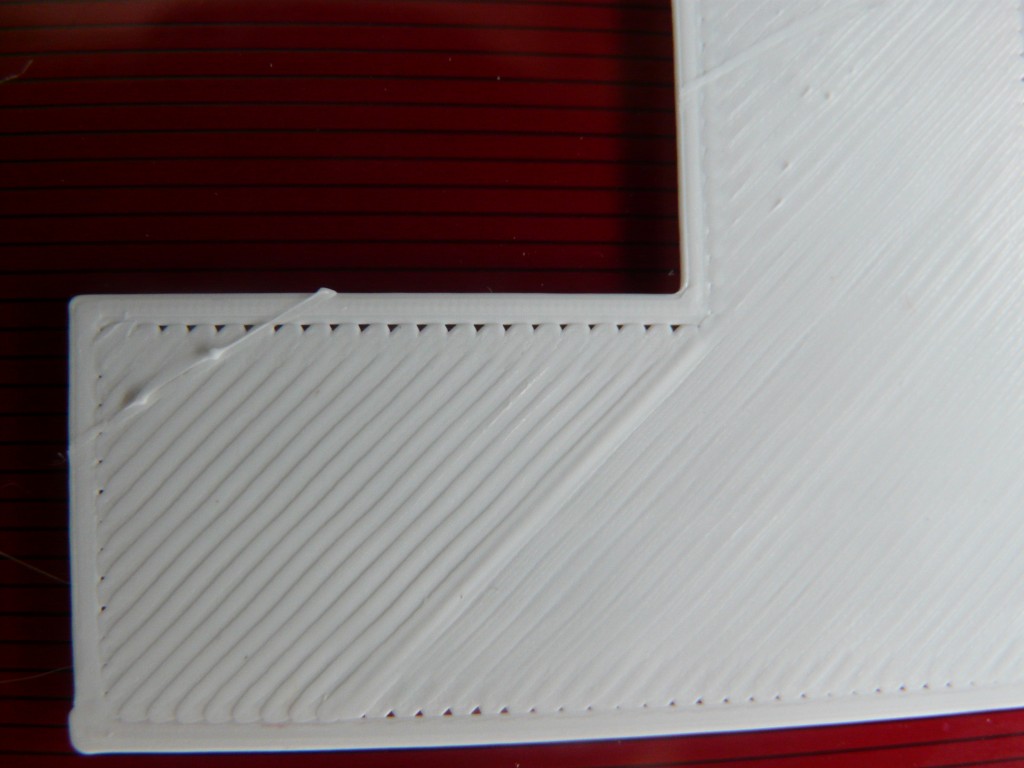

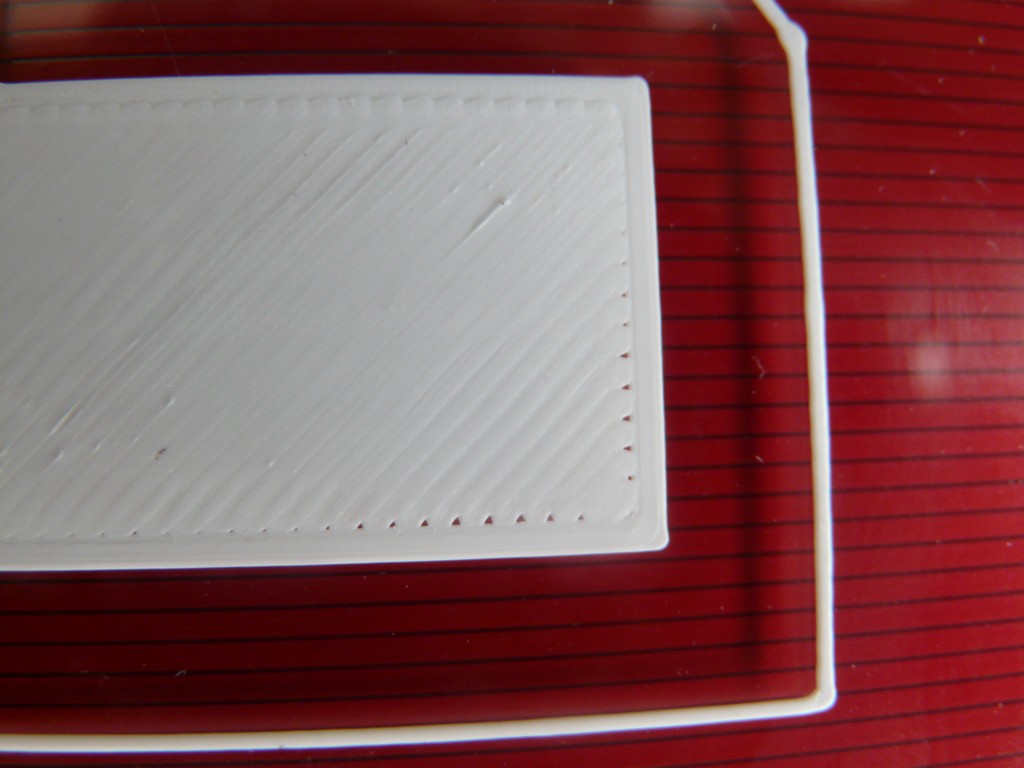

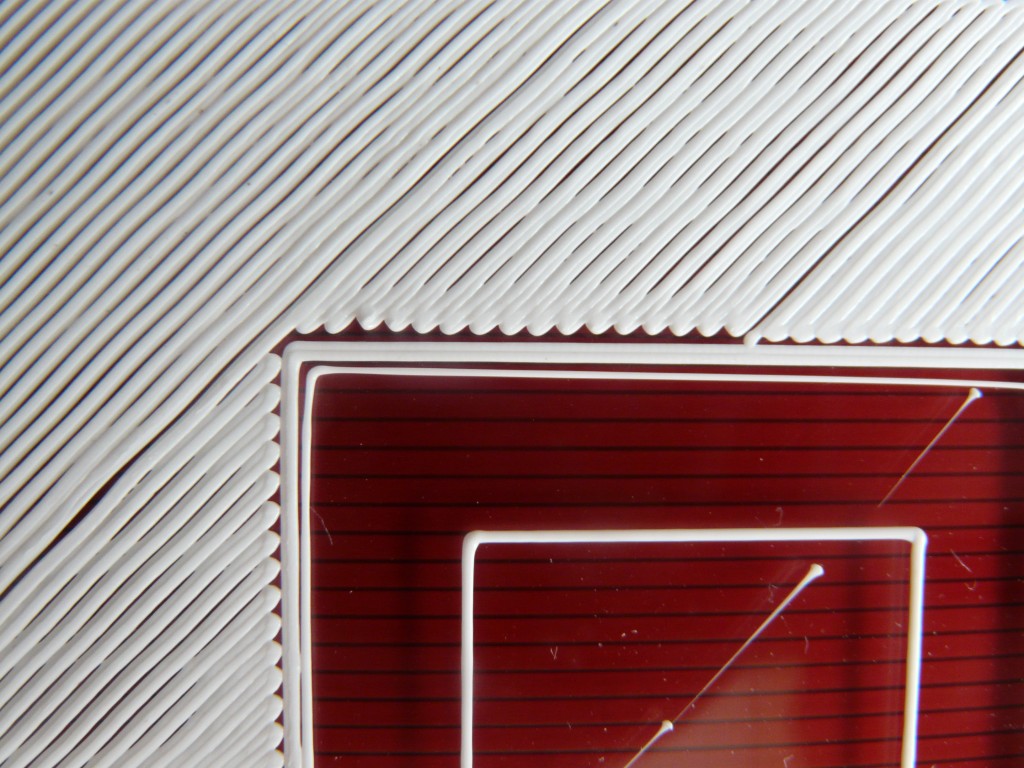

Apparently H is a good shape to identify backlash. In the photos it is clear that Mendel has some backlash, which doesn’t necessarily remain constant through similar moves. The backlash problem is worse than it appears because I have infill perimeter overlap set to 5%.

There is advice around in the RepRap community about how to tackle backlash, if you know where to look. There is a wiki page and a forum thread, but essentially the possible (mechanical) causes are:

- Filament dragging. A good spooling system is a requirement for quality prints.

- Pulley loose on the motor shaft

- Damage to belt. The timing belts have embedded wires to stop the belt from stretching. If these have fatigued and broken then the belt can stretch and needs to be replaced.

- Dirty smooth rods. This causes increased friction similar to 5.

- Over-constrained axes (locked bearings). Check the movement of the axes – is it smooth and free? Ideally the axes move under their own weight when tilting the axes.

- Under-constrained axes (loose bearings). If there is play in the axes in other directions (e.g. the x axes can move in the y and/or z directions) then this can look like backlash in the other axes.

- Other friction e.g. belt rubbing against mudguard washers at axes ends.

- Play in the hot end mounting.

- Motor not getting enough current

- Belt tension – too loose and movement gets lost in the slack, too tight and the friction prevents free movement

I have tried to list these in the order easiest to test. I found belt tension the hardest to judge so tried to only mess about with that once I had eliminated the rest.

I set the infill perimeter overlap to 0 to show whether I had cured the backlash, as leaving it at 5% could disguise a remaining issue.

The results are much better, although the problem still persists. I decreased the first layer height by adjusting the z endstop a little which probably helped, but there has been significant improvement on top of that.

To solve the problem I probably need to strip down Mendel and give the smooth bars and bearings a good clean, but with wanting to build a Prusa and OGGCamp and Brighton Mini Maker Faire coming up, as it aint too broke I won’t try and fix it until afterwards!